CORE_COMPETENCE

Product_Leaders

index_more

index_more_content

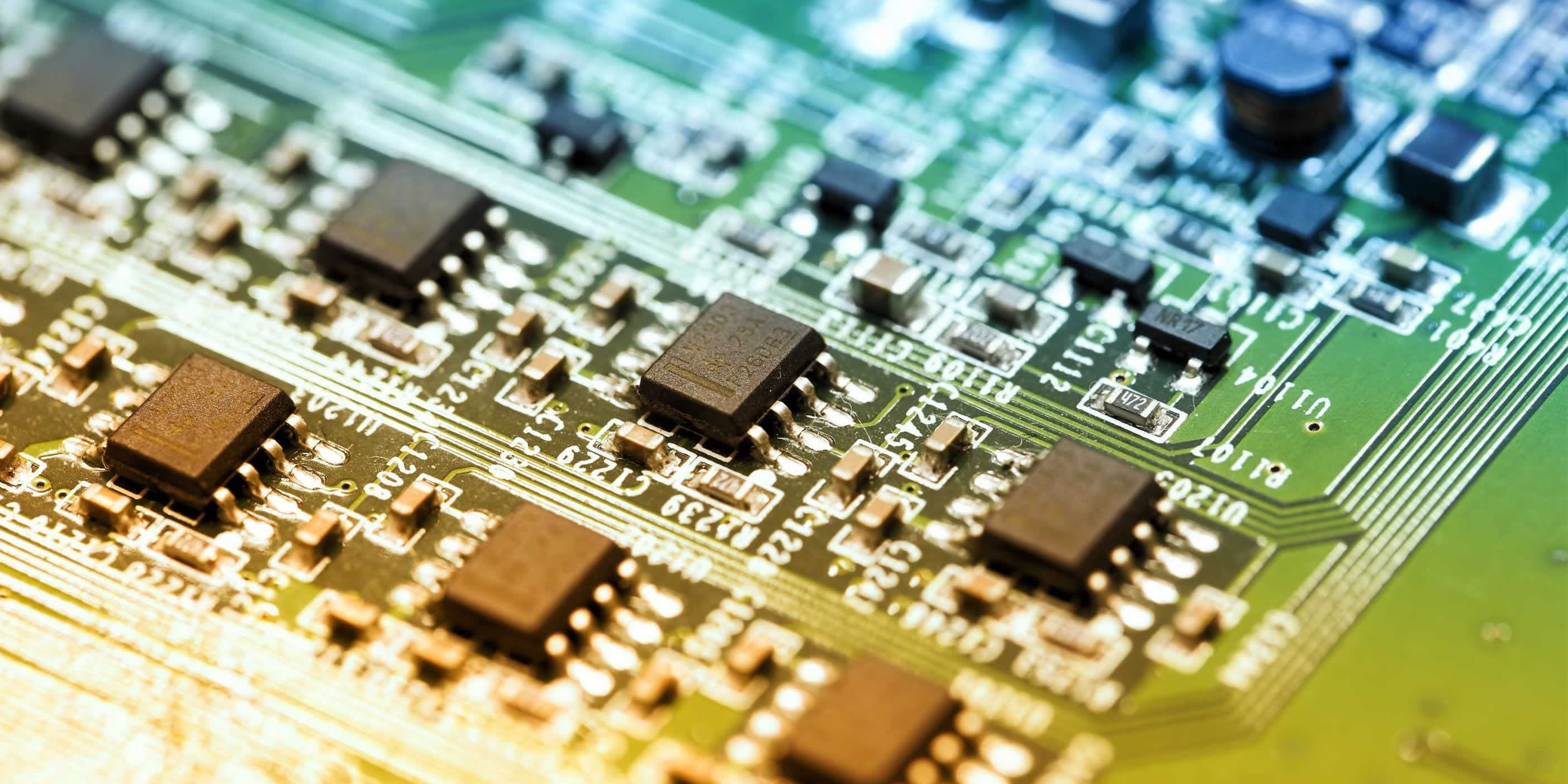

info_item01

info_item_content01

info_item02

info_item_content02

info_item03

info_item_content03

info_item04

info_item_content04

NEWS

NEWS

What are the market policies for capacitor media?

Market Policies for Capacitor Media

I. Introduction

Capacitor media, a crucial component in the electronics industry, plays a significant role in the functionality and efficiency of various electronic devices. These components store and release electrical energy, making them essential in applications ranging from consumer electronics to renewable energy systems. As the demand for electronic devices continues to rise, understanding the market policies surrounding capacitor media becomes increasingly important. This blog post will explore the various aspects of capacitor media, including its types, applications, market dynamics, regulatory frameworks, challenges, and future trends.

II. Understanding Capacitor Media

A. Types of Capacitors

Capacitors come in various types, each with unique characteristics and applications:

1. **Ceramic Capacitors**: Known for their small size and high stability, ceramic capacitors are widely used in high-frequency applications. They are often found in consumer electronics, such as smartphones and laptops.

2. **Electrolytic Capacitors**: These capacitors are polarized and typically used in power supply applications due to their high capacitance values. They are commonly found in audio equipment and power electronics.

3. **Film Capacitors**: Made from plastic film, these capacitors are known for their reliability and low loss. They are often used in applications requiring high voltage and stability, such as in industrial machinery.

4. **Tantalum Capacitors**: These capacitors offer high capacitance in a small package and are used in applications where space is limited, such as in mobile devices and medical equipment.

B. Applications of Capacitor Media

Capacitor media finds applications across various sectors:

1. **Consumer Electronics**: Capacitors are integral to devices like smartphones, tablets, and televisions, where they help manage power supply and signal processing.

2. **Automotive Industry**: In modern vehicles, capacitors are used in electronic control units, infotainment systems, and safety features, contributing to improved performance and efficiency.

3. **Industrial Applications**: Capacitors are essential in machinery and equipment, providing power factor correction and energy storage in industrial settings.

4. **Renewable Energy Systems**: Capacitors play a vital role in solar inverters and wind turbines, helping to stabilize power output and improve energy efficiency.

III. Market Dynamics

A. Demand and Supply Factors

The capacitor media market is influenced by several demand and supply factors:

1. **Technological Advancements**: Innovations in capacitor technology, such as the development of new materials and manufacturing processes, drive demand for more efficient and compact capacitors.

2. **Market Trends**: The growing trend towards miniaturization in electronics has led to an increased demand for smaller, high-capacity capacitors.

3. **Consumer Preferences**: As consumers become more environmentally conscious, there is a rising demand for sustainable and energy-efficient electronic products, influencing capacitor design and production.

B. Competitive Landscape

The capacitor media market is characterized by intense competition among key players:

1. **Key Players in the Market**: Major manufacturers, such as Murata Manufacturing, Vishay Intertechnology, and KEMET Corporation, dominate the market, leveraging their technological expertise and extensive distribution networks.

2. **Market Share Analysis**: The market is segmented based on capacitor type, application, and geography, with each segment exhibiting unique growth patterns and competitive dynamics.

3. **Pricing Strategies**: Companies often adopt competitive pricing strategies to capture market share, balancing cost with quality to meet consumer expectations.

IV. Regulatory Framework

A. International Standards and Compliance

The capacitor media market is subject to various international standards and compliance requirements:

1. **IEC Standards**: The International Electrotechnical Commission (IEC) sets standards for electrical components, including capacitors, ensuring safety and performance.

2. **RoHS Compliance**: The Restriction of Hazardous Substances (RoHS) directive limits the use of specific hazardous materials in electronic products, influencing capacitor manufacturing processes.

B. National Regulations

In addition to international standards, national regulations also play a crucial role:

1. **Environmental Regulations**: Governments worldwide are implementing stricter environmental regulations, pushing manufacturers to adopt sustainable practices in capacitor production.

2. **Safety Standards**: Compliance with safety standards is essential to ensure the reliability and safety of capacitors in various applications, particularly in automotive and industrial sectors.

V. Market Entry Strategies

A. Market Research and Analysis

For companies looking to enter the capacitor media market, thorough market research and analysis are essential. Understanding market trends, consumer preferences, and competitive dynamics can help businesses identify opportunities and develop effective strategies.

B. Distribution Channels

Choosing the right distribution channels is crucial for market penetration:

1. **Direct Sales**: Companies may opt for direct sales to establish a strong relationship with customers and gain insights into their needs.

2. **Distributors and Wholesalers**: Partnering with distributors and wholesalers can help companies reach a broader audience and streamline the supply chain.

C. Marketing Strategies

Effective marketing strategies are vital for brand positioning and customer engagement:

1. **Branding and Positioning**: Developing a strong brand identity and positioning in the market can differentiate a company from its competitors.

2. **Digital Marketing Approaches**: Leveraging digital marketing channels, such as social media and online advertising, can enhance visibility and attract potential customers.

VI. Challenges in the Capacitor Media Market

Despite the growth potential, the capacitor media market faces several challenges:

A. Supply Chain Disruptions

Global supply chain disruptions, exacerbated by events such as the COVID-19 pandemic, have impacted the availability of raw materials and components, leading to delays and increased costs.

B. Raw Material Costs

Fluctuations in raw material prices, particularly for materials like tantalum and aluminum, can affect production costs and profit margins for capacitor manufacturers.

C. Technological Changes

Rapid technological advancements require manufacturers to continuously innovate and adapt their products to meet evolving consumer demands and industry standards.

D. Environmental Concerns

As environmental awareness grows, manufacturers face pressure to adopt sustainable practices and reduce the environmental impact of capacitor production.

VII. Future Trends and Opportunities

The capacitor media market is poised for growth, driven by several future trends and opportunities:

A. Innovations in Capacitor Technology

Ongoing research and development efforts are leading to innovations in capacitor technology, such as the development of supercapacitors and advanced materials that enhance performance and efficiency.

B. Growth in Emerging Markets

Emerging markets, particularly in Asia-Pacific and Latin America, present significant growth opportunities for capacitor manufacturers as demand for electronic devices continues to rise.

C. Sustainability Initiatives

The push for sustainability is driving manufacturers to explore eco-friendly materials and production processes, creating opportunities for companies that prioritize environmental responsibility.

VIII. Conclusion

In conclusion, the capacitor media market is a dynamic and evolving sector that plays a critical role in the electronics industry. Understanding the various types of capacitors, their applications, market dynamics, regulatory frameworks, and challenges is essential for businesses looking to navigate this landscape successfully. As the market continues to grow, adapting to market policies and embracing innovation will be key to capitalizing on future opportunities. The capacitor media market holds promise for those willing to invest in research, sustainability, and strategic market entry, ensuring a bright future for this essential component of modern electronics.

2025-03-09

0

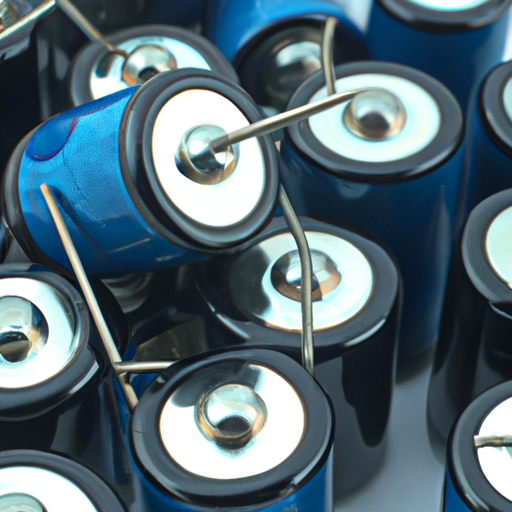

What is the purchase price of the latest battery capacitor?

What is the Purchase Price of the Latest Battery Capacitor?

I. Introduction

In the rapidly evolving landscape of modern technology, battery capacitors have emerged as critical components in various applications, from electric vehicles to renewable energy systems. These devices, which store and release electrical energy, play a pivotal role in enhancing the efficiency and performance of electronic systems. This article aims to explore the purchase price of the latest battery capacitors, shedding light on the factors that influence their costs and providing insights into current market trends.

II. Understanding Battery Capacitors

A. Explanation of Battery Capacitors and Their Function

Battery capacitors, often referred to as supercapacitors or ultracapacitors, differ significantly from traditional batteries. While batteries store energy chemically and release it through electrochemical reactions, capacitors store energy electrostatically and can discharge it almost instantaneously. This fundamental difference allows capacitors to deliver quick bursts of energy, making them ideal for applications requiring rapid charge and discharge cycles.

1. Difference Between Capacitors and Batteries

The primary distinction lies in their energy storage mechanisms. Batteries are designed for long-term energy storage and provide a steady output over extended periods. In contrast, capacitors excel in short-term energy storage, offering high power density and rapid charge/discharge capabilities. This makes them suitable for applications where quick energy delivery is essential.

2. Types of Battery Capacitors

Battery capacitors can be categorized into several types, with supercapacitors and ultracapacitors being the most prominent. Supercapacitors typically have higher energy density than traditional capacitors but lower than batteries, while ultracapacitors push the boundaries of energy storage, offering even greater performance.

B. Applications of Battery Capacitors

Battery capacitors find applications across various sectors:

1. Electric Vehicles

In electric vehicles (EVs), battery capacitors are used to provide additional power during acceleration and to capture energy during regenerative braking. This enhances the overall efficiency of the vehicle and extends its range.

2. Renewable Energy Systems

In renewable energy systems, such as solar and wind power, battery capacitors help stabilize energy output by storing excess energy generated during peak production times and releasing it when demand is high.

3. Consumer Electronics

From smartphones to laptops, battery capacitors are integral to consumer electronics, enabling quick charging and improving device performance.

4. Industrial Applications

In industrial settings, battery capacitors are used in uninterruptible power supplies (UPS), providing backup power during outages and ensuring the smooth operation of critical systems.

III. Factors Influencing the Purchase Price of Battery Capacitors

Understanding the purchase price of battery capacitors requires an examination of several influencing factors.

A. Material Costs

1. Types of Materials Used in Manufacturing

The materials used in the production of battery capacitors significantly impact their costs. Common materials include activated carbon, electrolytes, and conductive polymers. The quality and sourcing of these materials can vary, affecting the final price.

2. Impact of Raw Material Prices on Final Costs

Fluctuations in the prices of raw materials, driven by market demand and geopolitical factors, can lead to variations in the cost of battery capacitors. For instance, a rise in the price of activated carbon can directly increase the production costs of supercapacitors.

B. Manufacturing Processes

1. Complexity of Production

The manufacturing process for battery capacitors can be complex, involving multiple stages of production. This complexity can lead to higher labor and operational costs, which are reflected in the final purchase price.

2. Scale of Production and Economies of Scale

Larger manufacturers often benefit from economies of scale, allowing them to produce battery capacitors at a lower cost per unit. Smaller manufacturers may struggle to compete on price due to higher production costs.

C. Technological Advancements

1. Innovations in Battery Capacitor Technology

Technological advancements play a crucial role in shaping the pricing landscape. Innovations that enhance energy density, reduce production costs, or improve performance can lead to new products entering the market at varying price points.

2. Research and Development Costs

Investments in research and development (R&D) are essential for driving innovation in battery capacitor technology. These costs are often passed on to consumers, influencing the overall purchase price.

D. Market Demand and Supply Dynamics

1. Trends in the Electric Vehicle Market

The growing demand for electric vehicles has led to increased interest in battery capacitors, driving up prices as manufacturers strive to meet this demand.

2. Growth in Renewable Energy Sectors

As renewable energy sources gain traction, the demand for battery capacitors in energy storage systems is expected to rise, further influencing pricing dynamics.

3. Global Supply Chain Issues

Recent global supply chain disruptions have impacted the availability of raw materials and components, leading to increased costs for manufacturers and, consequently, higher prices for consumers.

IV. Current Market Prices of Battery Capacitors

A. Overview of the Latest Battery Capacitor Models

The market for battery capacitors is diverse, with several leading manufacturers offering a range of products. Companies like Maxwell Technologies, Panasonic, and Skeleton Technologies are at the forefront, providing innovative solutions tailored to various applications.

1. Leading Manufacturers and Their Offerings

Maxwell Technologies, for instance, specializes in ultracapacitors that are widely used in automotive and industrial applications. Panasonic offers a range of supercapacitors designed for consumer electronics, while Skeleton Technologies focuses on high-performance energy storage solutions.

2. Comparison of Specifications and Features

When comparing battery capacitors, specifications such as energy density, power density, cycle life, and operating temperature range are crucial. These factors can significantly influence the purchase price.

B. Price Ranges for Different Types of Battery Capacitors

1. Supercapacitors

The price of supercapacitors typically ranges from $0.10 to $0.50 per farad, depending on the manufacturer and specifications.

2. Ultracapacitors

Ultracapacitors, known for their higher energy density, can range from $0.50 to $2.00 per farad, reflecting their advanced technology and performance capabilities.

3. Hybrid Capacitors

Hybrid capacitors, which combine features of both batteries and capacitors, can vary widely in price, often falling between the ranges of supercapacitors and ultracapacitors.

C. Case Studies of Recent Purchases

1. Examples of Companies Investing in Battery Capacitors

Several companies have recently made significant investments in battery capacitors. For instance, Tesla has integrated supercapacitors into its energy storage solutions to enhance performance and efficiency.

2. Analysis of Pricing Strategies

Companies are adopting various pricing strategies based on market demand, production costs, and competitive positioning. Some manufacturers may offer discounts for bulk purchases, while others focus on premium pricing for high-performance products.

V. Future Trends in Battery Capacitor Pricing

A. Predictions for Price Changes in the Coming Years

As technology continues to advance, the pricing landscape for battery capacitors is expected to evolve. Innovations that enhance performance and reduce production costs may lead to lower prices in the long term.

1. Impact of Technological Advancements

Emerging technologies, such as new materials and manufacturing techniques, have the potential to revolutionize the battery capacitor market, driving down costs and improving performance.

2. Expected Shifts in Market Demand

As electric vehicles and renewable energy systems become more prevalent, the demand for battery capacitors is likely to increase, potentially leading to price fluctuations based on supply and demand dynamics.

B. Potential for Cost Reduction Through Innovation

1. New Materials and Manufacturing Techniques

Research into alternative materials and more efficient manufacturing processes could result in significant cost reductions, making battery capacitors more accessible to consumers and businesses alike.

2. Increased Competition Among Manufacturers

As more players enter the battery capacitor market, competition is expected to intensify, leading to price reductions and improved product offerings.

VI. Conclusion

In summary, the purchase price of the latest battery capacitors is influenced by a myriad of factors, including material costs, manufacturing processes, technological advancements, and market dynamics. Understanding these elements is crucial for consumers and businesses looking to invest in battery capacitors. As the market continues to evolve, staying informed about pricing trends and innovations will be essential for making informed purchasing decisions. The future of battery capacitors holds promise, with potential for cost reductions and enhanced performance, paving the way for broader adoption across various industries.

VII. References

- Maxwell Technologies. (2023). Product Catalog.

- Panasonic. (2023). Supercapacitor Solutions.

- Skeleton Technologies. (2023). Energy Storage Solutions.

- Market Research Reports on Battery Capacitors. (2023). Industry Analysis and Trends.

2025-03-08

0

What components and modules are included in capacitor measurement?

What Components and Modules are Included in Capacitor Measurement?

I. Introduction

Capacitor measurement is a critical aspect of electronics and electrical engineering, involving the assessment of a capacitor's ability to store electrical energy. Accurate capacitor measurement is essential for ensuring the reliability and performance of electronic circuits. This blog post will explore the various components and modules involved in capacitor measurement, providing a comprehensive understanding of the subject.

II. Basic Concepts of Capacitance

A. Definition of Capacitance

Capacitance is defined as the ability of a capacitor to store an electrical charge. It is a fundamental property of capacitors, which are passive electronic components used in a wide range of applications, from filtering signals to energy storage.

B. Units of Measurement

Capacitance is measured in farads (F), with common subunits including microfarads (µF), nanofarads (nF), and picofarads (pF). One farad is defined as the capacitance of a capacitor that stores one coulomb of charge at one volt.

C. Factors Affecting Capacitance

Several factors influence capacitance, including:

Dielectric Material: The type of dielectric material used between the capacitor plates affects its capacitance. Materials with higher permittivity increase capacitance.

Plate Area: The larger the area of the capacitor plates, the greater the capacitance.

Distance Between Plates: The closer the plates are to each other, the higher the capacitance, as the electric field strength increases.

III. Key Components in Capacitor Measurement

A. Capacitor Under Test (CUT)

The capacitor under test (CUT) is the specific capacitor being measured. Different types of capacitors, such as electrolytic, ceramic, and film capacitors, have unique characteristics that can affect measurement results.

1. **Types of Capacitors**:

- **Electrolytic Capacitors**: Known for their high capacitance values, these are polarized and must be connected correctly in a circuit.

- **Ceramic Capacitors**: These are non-polarized and are often used in high-frequency applications.

- **Film Capacitors**: Known for their stability and low losses, these capacitors are used in precision applications.

2. **Characteristics of CUT**: The capacitance value, equivalent series resistance (ESR), and leakage current are critical characteristics to consider during measurement.

B. Measurement Instruments

Accurate measurement of capacitance requires specialized instruments. The most common tools include:

1. **LCR Meters**:

- **Functionality**: LCR meters measure inductance (L), capacitance (C), and resistance (R) of components.

- **Types of LCR Meters**: Handheld LCR meters are portable and suitable for fieldwork, while bench-top models offer higher precision and additional features.

2. **Multimeters**:

- **Capacitance Measurement Feature**: Many digital multimeters (DMMs) include a capacitance measurement function, allowing for quick checks.

- **Limitations**: Multimeters may not provide the same level of accuracy or detail as dedicated LCR meters.

3. **Oscilloscopes**:

- **Use in Capacitor Measurement**: Oscilloscopes can visualize voltage and current waveforms, helping to analyze capacitor behavior in circuits.

- **Advantages and Disadvantages**: While oscilloscopes provide detailed insights, they require more setup and expertise compared to simpler measurement tools.

C. Test Fixtures

Proper test fixtures are essential for accurate measurements. They ensure good electrical contact and minimize parasitic effects.

1. **Importance of Proper Test Fixtures**: A well-designed test fixture can significantly reduce measurement errors caused by stray capacitance and inductance.

2. **Types of Test Fixtures**:

- **Soldered Fixtures**: Provide a permanent connection but may not be suitable for frequent testing.

- **Clip-on Fixtures**: Allow for quick connections and disconnections, making them ideal for testing multiple capacitors.

D. Calibration Standards

Calibration is crucial for ensuring measurement accuracy. Regular calibration against known standards helps maintain the reliability of measurement instruments.

1. **Importance of Calibration**: Calibration ensures that measurement devices provide accurate readings, which is vital for quality control and research.

2. **Common Calibration Standards Used**: Standards such as those from the National Institute of Standards and Technology (NIST) are often used to calibrate measurement instruments.

IV. Measurement Modules and Techniques

A. AC Measurement Techniques

1. **Impedance Measurement**: This technique involves applying an AC signal to the capacitor and measuring the resulting current and voltage to calculate capacitance and ESR.

2. **Phase Angle Measurement**: The phase angle between voltage and current can provide insights into the capacitor's behavior, particularly in AC circuits.

B. DC Measurement Techniques

1. **Charge and Discharge Method**: This method involves charging the capacitor to a known voltage and measuring the time it takes to discharge through a known resistor to calculate capacitance.

2. **Leakage Current Measurement**: Measuring the leakage current helps assess the quality and reliability of the capacitor, especially in high-voltage applications.

C. Frequency Response Analysis

1. **Importance in Capacitor Measurement**: Frequency response analysis helps understand how capacitance changes with frequency, which is crucial for high-frequency applications.

2. **Techniques Used**: Techniques such as Bode plots and Nyquist plots are commonly used to analyze frequency response.

D. Temperature and Environmental Considerations

1. **Effects of Temperature on Capacitance**: Capacitance can vary with temperature, so measurements should be taken under controlled conditions.

2. **Environmental Factors to Consider**: Humidity, pressure, and other environmental factors can also affect measurements, making it essential to account for these variables.

V. Data Analysis and Interpretation

A. Understanding Measurement Results

1. **Interpreting Capacitance Values**: Understanding the significance of measured capacitance values is crucial for evaluating capacitor performance.

2. **Analyzing Impedance and Phase Angle**: Analyzing these parameters can provide insights into the capacitor's behavior in different circuit conditions.

B. Common Issues and Troubleshooting

1. **Measurement Errors**: Errors can arise from instrument calibration, environmental factors, or improper connections.

2. **Techniques for Error Minimization**: Regular calibration, using proper test fixtures, and following best practices can help minimize measurement errors.

VI. Applications of Capacitor Measurement

Capacitor measurement plays a vital role in various fields:

A. Electronics and Circuit Design

Accurate capacitor measurement is essential for designing reliable electronic circuits, ensuring that components function as intended.

B. Quality Control in Manufacturing

In manufacturing, capacitor measurement is used to ensure that components meet specified standards and performance criteria.

C. Research and Development

In R&D, precise measurements are crucial for developing new technologies and improving existing products.

D. Maintenance and Repair

Capacitor measurement is also important in maintenance and repair, helping technicians diagnose issues in electronic devices.

VII. Conclusion

In summary, capacitor measurement is a multifaceted process involving various components, instruments, and techniques. Understanding these elements is essential for accurate measurements and reliable electronic designs. As technology advances, the methods and tools for capacitor measurement will continue to evolve, highlighting the importance of continuous learning in this field.

VIII. References

A. Suggested Reading Materials

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

- "Capacitors: Technology and Trends" by John Smith

B. Relevant Standards and Guidelines

- IEC 60384: Standards for fixed capacitors

- NIST Calibration Guidelines

C. Online Resources and Tools for Further Learning

- National Instruments (NI) website for measurement tools

- Online forums and communities for electronics enthusiasts

This blog post provides a comprehensive overview of the components and modules involved in capacitor measurement, emphasizing the importance of accuracy and the various techniques used in the field.

2025-03-07

0